(PDF) Design of Impact stone crusher machine

2019年5月31日 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to

learn more

Impact crusher kinematics: The dynamics of an impact swing

2024年3月1日 Briefly described: In the crushing chamber of an impact crusher, particles (natural stone, mineral-based recycling material, or asphalt fragments – commonly with a

learn more

How Impact Crushers Work: A Comprehensive

2023年3月11日 An impact crusher is a machine used to crush materials by impact energy. It works by feeding the material into a rotating rotor, which is equipped with a series of hammers. As the rotor spins, the hammers

learn more

Modelling of output and power consumption in vertical shaft impact ...

2008年8月1日 The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. A comprehensive understanding of the physical phenomena that

learn more

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

2011年5月10日 OPERATING PRINCIPLE OF THE HORIZONTAL SHAFT IMPACT CRUSHER The Impact Crusher Machine rotor revolves in fixed direction by means of

learn more

Impact Crusher - an overview ScienceDirect Topics

Impact crushers (e.g., hammer mills and impact mills) employ sharp blows applied at high speed to free-falling rocks where comminution is by impact rather than compression. The

learn more

Optimization of key components of impact crusher based on

2020年6月1日 Inspired by the bionic wear-resistant structure, the shape and parameters of an impact crusher chamber are optimized. Taking both crusher strength and crushing

learn more

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 Impact crushers are most commonly used in stone quarrying industry for making fine-grained stones used in road and building materials. The impact crusher as

learn more

Design and Random Vibrational Analysis of Horizontal Impact Hammer Crusher

2020年10月31日 All research works are done on the impact horizontal crusher through modeling in SOLIDWORKS, and Random Vibrational analysis was performed using

learn more

(PDF) A performance model for impact crushers

2002年10月1日 In this paper we develop a performance model for impact crushers. The product size distribution is obtained as a function of the crusher’s rotor radius and angular velocity, the feed rate and...

learn more

I-140 Impact Crusher Horizontal Impactor

4 天之前 The Finlay® I-140 tracked impact crusher shapes the future through innovation. This new generation impact crusher with redefined style and advanced technological design gives improved material flow and

learn more

Energy considerations in compressive and impact crushing

2008年8月1日 1.2.. Production challenges in miningIn a typical mining application, a primary crusher reduces the size of blasted rock; from several hundred mm down to 0–250. mm.. A secondary crusher then reduces the size from those 250 mm down to about 0–70 mm, and is then followed by a tertiary crusher in closed circuit with a screen.The final

learn more

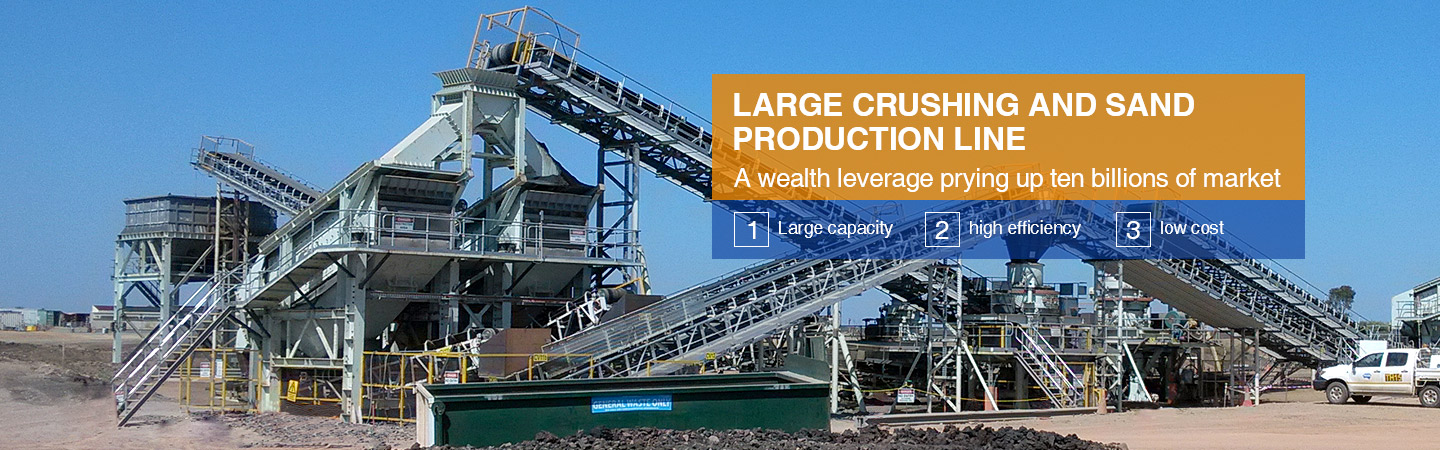

Crushers, Mobile Crushers, Jaw Crushers, Cone Crushers, Impact

2022年6月14日 Impact crushers from Kefid is of 20 years manufacturing and using experience, which has won worldwide reputation due to its economical price, high capacity, high reduction, fine grain shape, easy adjustment and easy maintenance. We have been a leading manufactuer of cone crushers for over 20 years, CS Cone Crusher, HC Cone

learn more

Mathematical modeling of a vertical shaft impact crusher using

2017年9月1日 The Andersen/Awachie/Whiten model of the cone crusher has been applied in modeling the performance of a 264 kW vertical shaft impact crusher producing manufactured sand. The model has been supplemented by equations describing the variation of parameter K 3 in the classification function and the T 10 parameter of the

learn more

Impact Crusher Trakpactor 320 Powerscreen

4 天之前 Tier 4F VGF: 36,560kg Tier 4F Pre-screen: 38,160kg. The Powerscreen® Trakpactor 320 is a mid-sized horizontal impact crusher designed to offer operators and contractors both excellent reduction and high consistency of product shape for performance in quarry and recycling applications. With track mobility, the impactor is capable of

learn more

QI353 HSI impact crusher - SRP

Equipment. Sandvik Prisec™ HSI. Feed opening. 1360 x 800 mm (54 x 31 in.) mm. Max. feed size. Up to 800 mm (32 in.) Capacity. Up to 500 mtph (551 stph) Sandvik QI353 mid-sized mobile impact crusher featuring Sandvik Prisec HSI impactor technology.

learn more

Impact Crusher - an overview ScienceDirect Topics

The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness. Effect of process conditions on the production capacity of crushed materials is listed in Table 8.10. Table 8.10.

learn more

Mobile Impact Crushers, QI Mobile Impact Crusher - SRP

500 (551) 1. Wheeled range of impact crushers. Our range of wheeled impact crushers are designed for flexibility, high productivity and ease of transport. Fully assembled on a single trailer frame, we have designed these units to provide complete versatility combined with a low operating cost due to electric operation. Model.

learn more

conception of impact crusher

Impact Crushers Design And Calculations Pages. In the back of the production of impact crusher in the process of constructing basic attribute, the plate hammer velocity and crushing material finished product size, equipment and the plate hammer wear are closely linked. impact crusherso how to reasonable optimization has become the key point of

learn more

Impact crusher thyssenkrupp Polysius Crushing Technologies

The thyssenkrupp Polysius Impact Crusher produces a single stage perfect feed material for a vertical roller mill. thyssenkrupp Polysius Impact Crushers are installed as stationary, semi-mobile or mobile crushing plants with plant capacities of more then 4,000 t/h. Impact crusher - Crushers for medium hard material.

learn more

conception of impact crusher

conception of impact crusher. ... Jul 29, 2013 Kleemann Mineral Technologies' new 450tph Mobirex MR 130 ZS EVO impact crusher from Wirtgen America is ideally suited for processing recycled concrete aggregate (RCA) and reclaimed asphalt pavement (RAP), and aggregates. The EVO concept matches refinements for all individual components with a

learn more

Impact Crusher Powerscreen Impact Crushers

Impact Crushers. Power Screening is your leading source for impact crusher sales, rental, parts and service in the Rocky Mountain region. With branches in Henderson, Colorado, Albuquerque, New Mexico, and Salt Lake City,

learn more

Impact Crusher For Sale With 30-800 t/h

The capacity of PF impact crusher is 30-800 t/h. The biggest capacity machine is PF1820, its capacity is 600-800 t/h. Skip to content. Menu. ... new ideas, and new conception. The impactor crusher, which can meet

learn more

冲唤破碎机 - 百度百科

Impact crusher is ideal choice for crushing and screening. It features reasonable structure, high productivity, easy operation and maintenance and safe performance. The most outstanding advantage of the impact crusher is that its finished powder is in good, cubic shape and without tensility and cranny.

learn more

Simulation and optimization of gyratory crusher

2020年10月1日 1. Introduction. The gyratory crusher is widely used in primary crushing of metal ore such as iron ore and copper ore due to its high productivity and large feed inlet [[1], [2], [3]].In recent years, with the growth of the world's population, the development of urbanization and the improvement of living standards, the demand for the ore continues

learn more

Impact crushers - high-quality impactors - Metso

Impact crushers produce high-quality end products efficiently. Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes. As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fast-moving rocks against the walls of the crushing chamber and each ...

learn more

How does an impact crusher work? RUBBLE MASTER

The higher the abrasion, hardness, and fines-content the faster the wear. The rotor body holds hammers in place through a sliding system (see picture) or they are lifted in and wedged in place. Impact Crusher Models RUBBLE MASTER offers a large range of mobile Impact Crushers ranging from 90 to 385 TPH. RM 100GO!

learn more

Crushers – LT Construction Mining Machinery

LT Reversible Impactors are proven equipment for secondary and tertiary crushing applications. The Reversible Impactors are improved versions of hammer crushers. The hammer size impact blocks designs are made rugged and heavy to handle demanding crushing requirements in secondary and tertiary applications. The symmetrical geometry

learn more

Multi-Objective Optimization of Impact Crusher Rotor Based ...

摘要:. A method of multi-objective optimization was proposed to improve the quality of crushed materials and protect hammers of impact crusher from fatigue failure.This method was driven by the minimum breakable size of the impact crusher and the maximum deformation.The Central Composite Design (CCD) experiment method was used to

learn more

Simulation and experimental study on the stone powder

2020年3月1日 At present, the main crushing equipment utilized in manufactured sand production is the cone crusher and the vertical shaft impact (VSI) crusher. The ability to limit the amount of stone powder produced is the major advantage of the cone crusher [1], [2], [3]. However, for most particle sizes, the fragment shape is poor [4].

learn more