6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年10月8日 This blog outlines 6 types of coal crushers, and their pros and cons, to aid your coal crusher selection.

learn more

Coal Crusher - MoleDive Rock and Ore Crushing and

Classified as a high-efficiency fine crushing device, MoleDive’s coal crusher is specifically engineered to break down large coal chunks into smaller, more manageable fragments.

learn more

Primary Coal Crushers Grow to Meet Demand - Coal Age

2009年9月12日 By Steve Fiscor, Editor-in-Chief. The process of crushing coal to a more manageable size is an important step in the processing chain. Primary crushers reduce a

learn more

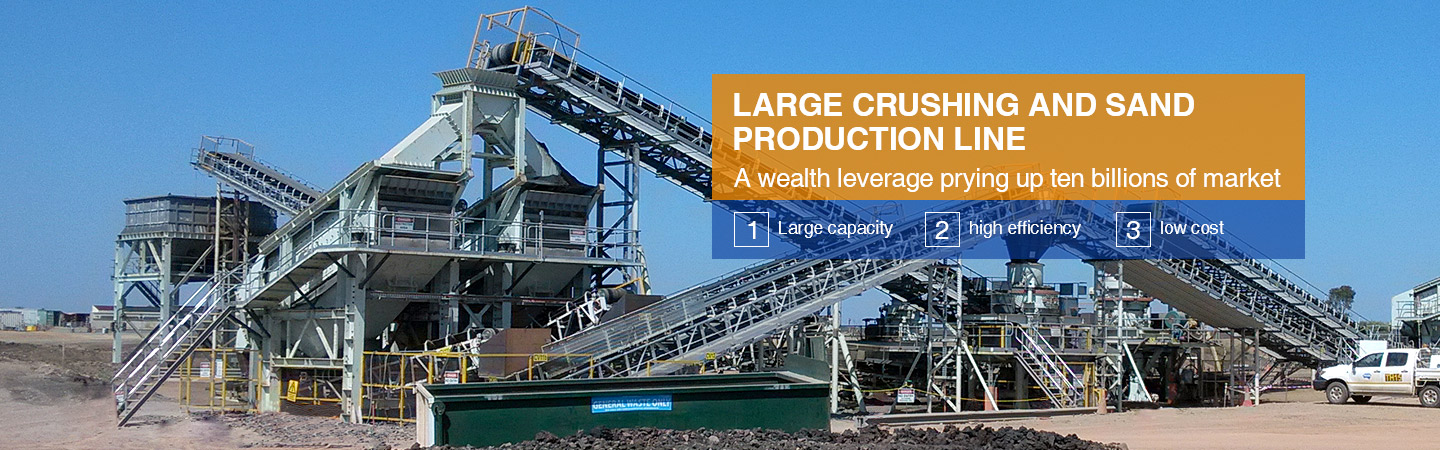

Stone crushing equipment: a vital contributor to

2020年1月3日 Global stone crushing equipment market size is anticipated to hit US$8.5 billion by 2025, with consistent deployment of jaw and impact crushers. A rise in urbanisation, along with the increase in transportation

learn more

coal crushing - Gaofu

Coal crushing solution. Coal has a wide range of uses, which can be summarized into three main uses according to its purpose: thermal coal, coking coal, coal chemical industry

learn more

How Do I Know Which Primary Crusher Is Best

2019年10月17日 The primary reduction of coal from open pit or underground sources to a transportable and marketable product size, as well as further processing by cleaning plants, can be accomplished with

learn more

煤炭破碎机_百度百科

Coal crusher. 别 名. 双级破碎机. 功 能. 主要是针对高水份含量的煤炭难破碎的难题. 用 途. 一般用作粉碎煤矸石往煤里参,或者粉碎煤炭做生活之用. 目录. 1 产品特点. 2 产品用途. 3 工作原理. 4 产品优点. 产品特点. 播报. 编辑.

learn more

Chapter 75 Operation and Maintenance of Coal

2023年2月13日 Coal screen and coal crusher are the key equipment of coal conveying system in thermal power plant (Lang 1998;Zhaoetal2001a, b). Coal conveying system

learn more

Coal Crushers, Shredders, Mills for Mining Power

2023年8月4日 We make many types of coal crushing equipment, like our ACC Series Rolling Ring Crusher with capacities ranging from 630–2,350 TPH. We also offer

learn more

Coal Crushers, 1.6mm / 4.75mm Final Particle

LC-201 model is recommended for crushing 2in (51mm) and smaller samples. It processes at a maximum rate of about 1,000lb (454kg) of coal material per hour. The final size is approximately 1/16in (1.6mm) and the

learn more

Analisis Efektivitas Coal Crusher Dengan Metode Overall ...

2019年10月6日 Berdasarkan hasil perhitungan nilai rata-rata OEE pada mesin coal crusher pada bulan Agustus 2018 sampai Maret 2019 sebesar 55,5% dengan nilai availability rate 78%, performance rate 77%, dan quality rate 99,9% yang dimana masih jauh dengan standar dunia yaitu Avaibility >90% performance rate >95% quality rate >99,9% .

learn more

Optimal energy control of a crushing process based on vertical shaft ...

2016年1月15日 In this work, the coal crusher in [8] is assumed to be a VSI crushing machine and therefore, the same system is used to simulate the optimal energy control strategy of a VSI crushing process developed in this research work. This assumption is reasonable since for pulverized hard coal-fired power plants such as those found in

learn more

coal crusher morocco - LinkedIn

2024年1月9日 Empowering Coal Mining in Morocco with SBM's Advanced Coal Crusher Morocco, with its rich coal reserves, is on the path to harnessing its energy potential through advanced mining technologies. SBM ...

learn more

Coal Mining Crusher royalty-free images - Shutterstock

2023年12月17日 Find Coal Mining Crusher stock images in HD and millions of other royalty-free stock photos, 3D objects, illustrations and vectors in the Shutterstock collection. Thousands of new, high-quality pictures added every day.

learn more

Optimal operation of coal conveying systems assembled with crushers ...

2017年7月15日 The coal feed rate, belt speed and crusher rotational speed are taken as the optimization variables; and, the energy cost, with consideration of time-of-use (TOU) tariff, is formulated as the objective function. Next, basing on the above open loop optimization problem, a closed-loop model predictive control (MPC) strategy is

learn more

Experimental study of coal liberation: Electrical disintegration

2009年7月1日 Ostuka Steel Company AR-85 roll crusher was used for the experiments. The roll crusher tests were carried out under various conditions and roll crusher product with a similar size distribution as the ED product was investigated further. Coal feed weight was 100 g, the same as in the ED test. 3.3. Comminution products analysis

learn more

Coal Crusher - crusher, grinding mill, equipment

Taiwan supplier of crusher, grinding mill, equipment. As a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any size-reduction requirements, including quarry, aggregate, grinding production and complete plant plan. We also supply individual ...

learn more

(PDF) Vibration Test and Shock Absorption of Coal Crusher Chambers

2020年9月15日 The coal crusher generates large vibrations when crushing coal blocks, which can affect the equipment itself, as well as the safety of the structure. In order to study the dynamic characteristics ...

learn more

Coal Pulverizer and Coal Crusher Reliability Mobil

2018年3月20日 Challenge: Coal pulverizer reliability. Repairs and even routine maintenance are time-consuming and costly due to difficult operating conditions. Operating temperatures can be high and coal dust is typically present. Careful protection of this asset is critical to reliability and productivity, as well as personnel safety.

learn more

(PDF) Experimental study of coal liberation: Electrical

Int. J. Miner. Process. 92 (2009) 7–14 Contents lists available at ScienceDirect Int. J. Miner. Process. j o u r n a l h o m e p a g e : w w w. e l s ev i e r. c o m / l o c a t e / i j m i n p r o Experimental study of coal liberation: Electrical disintegration versus roll-crusher comminution M. Ito ⁎,1, S. Owada, T. Nishimura 2, T. Ota 3 Faculty of Science and

learn more

Rub-Impact Fault Diagnosis of a Coal Crusher Machine by

2021年7月22日 The crusher was running in a coal handling plant in steel plant. A simple schematic diagram of coal crusher with sensor orientation on bearing housing, a 3D crusher model and a photograph of Crusher NDE bearing with two sensors fixed in radial and horizontal direction are shown in Figs. 4, 5 and 6 respectively. Crusher assembly was

learn more

coal processing plant crusher - LinkedIn

2024年1月10日 Coal preparation plant crusher and grinding mill. 10,000 tons per day coal processing plant. price coal crusher plant 2000 ton hour. Silica sand production silica sand crusher. How to increase the ...

learn more

coal crusher investissement - selepackitalia

The raw coal in the power generation station is generally at 300mm, usually adopting coal sizer crusher as primary crusher, and ring hammer crusher, four tooth roll crusher or reversible hammer crusher as secondary crusher, to crushing the raw coal to be 1030mm for the fuel of circulating fluidized bedboiler or the raw material of coal powder ...

learn more

Coal Crusher Manufacturer in Gujarat Coal Crusher

2024年6月23日 We are actually a prominent Coal Crusher Manufacturer in Gujarat. We are providing high-quality and efficient coal-crushing (Coal Crusher)solutions to various industries.

learn more

Liberation characteristics of coal middlings comminuted by jaw crusher ...

2013年9月1日 Full densimetric analyses indicate that mineral liberation of the product crushed by the jaw crusher is better than that by the ball mill at each fraction. For sizes of −0.125 mm + 0.074 mm and −0.074 mm, yields of the product with ash content 11% comminuted by jaw crusher are nearly 20% higher than that by the ball mill.

learn more

Automatic Mild Steel Coal Crusher Machine, Capacity: 1 TPH

We are engaged in manufacturing and supplying of Construction Equipment.Our product range includes Coal Crusher, Brick Making Machine and Pug Mill.The offered products are designed and developed under the supervision of experienced professionals using superior quality of raw material, which is procured from reliable vendors of the market and

learn more

Assessment of emission-source contribution to spatial

2021年7月1日 Assessment of emission-source contribution to spatial dispersion for coal crusher agglomeration using prognostic model @article{Srivastava2021AssessmentOE, title={Assessment of emission-source contribution to spatial dispersion for coal crusher agglomeration using prognostic model}, author={Amartanshu Srivastava and Suresh

learn more

Optimization of particle size distribution in circulating fluidized ...

2019年6月15日 The results were applied in optimizing an industrial-scale crushing system and two-toothed roll crusher of a coal gangue-fired power plant. Investigations demonstrated that the PSD can improve the combustion efficiencies of the CFB significantly by 3%, as well as a 3× extension of the original service life of the two-toothed roll crusher. ...

learn more