Design of a small-scale granite stone crusher - ScienceDirect

2020年1月1日 The small scale granite stone crusher was designed to crush stones of approximately 25-135mm to about 24-20.2mm in size. SOLID WORKS was used as a

learn more

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge crushing rate and high

learn more

Small Scale Mechanized Stone Crusher, Mechanical Design

2021年7月26日 jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into

learn more

Stone Crushers: A Technical Review on Significant Part of

2022年5月13日 Crushers are one of the essential quarrying machines used in foresaid industries which are generally used to reduce the size of large size rocks into small

learn more

(PDF) Design and Performance Evaluation of a

2021年10月7日 Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher. The main objective is to design impact stone crusher.

learn more

« DESIGN OF A STONES CRUSHER MACHINE» - rufso

2022年4月11日 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held

learn more

Design and Random Vibrational Analysis of Horizontal Impact Hammer Crusher

2020年10月31日 The crusher is a component [ 3] that is designed to reduce the large solid chunks of raw material into smaller rocks, gravel, or rock dust. Crushers may be used to

learn more

[PDF] Design And Development Of A Small Capacity Stone Crusher ...

2011年10月1日 So development of smaller sized crusher is today’s requirement. In this paper detailed design and analysis of proposed small size stone crusher mechanism is

learn more

(PDF) Design of a small-scale granite stone

2020年1月1日 The small scale granite stone crusher was designed to crush stones of approximately 25-135mm to about 24-20.2mm in size. SOLID WORKS was used as a stress analysis tool on the gear (main...

learn more

Small Scale Mechanized Stone Crusher, Mechanical Design

2021年7月26日 jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates. This mechanism will help to evaluate its effectiveness in comparison with other different types of mechanisms in use especially the double toggle and the modified single toggle

learn more

Design, Fabrication and Testing of a Double Roll Crusher

2024年3月1日 A double roll crusher consists of two rolls. Crushing takes place between two cylindrical rolls with each rotating about a concentric horizontal shaft in opposite directions. This is the most common of all roll crushers. Grinding machines are used for reducing crushed particles into their smallest functional sizes.

learn more

Design of impact stone crusher machine - ResearchGate

2024年3月17日 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of ...

learn more

Effect of demolished concrete and stone crusher dust on

2021年1月1日 Stone crusher dust can replace up to 50% sand in production of paver blocks without decrease in physical mechanical strength [16]. In this study, NCA was replaced by coarse RCA and river sand by SCD for manufacturing of M−40 grade concrete paver blocks and mechanical durability performance were evaluated. ... To finalize the

learn more

Design of impact stone crusher machine - IJSER

2023年2月7日 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of the desired size at the bottom, end or at sides to allow crushed material to escape through them. Impact stone crusher is used with soft

learn more

Design and Performance Evaluation of a Stone Crusher

The machine was fabricated using locally available materials. The fabricated stone crusher was tested and the actual capacity was found to be 301 kg/h with a through-put efficiency of 75.4 %. The crushed products were well graded with 1.89 coefficient of gradation and uniformity coefficient of 10.22.

learn more

[PDF] Computer aided design of jaw crusher Semantic Scholar

2010年5月13日 Computer Aided Design and Analysis of Swing Jaw Plate of Jaw Crusher. A. Bharule. Engineering. 2009. Traditionally, stiffness of swing plates has not been varied with changes in rock strength. Rock strength has only been of interest because of the need to know the maximum force exerted by the toggle. Expand. 9. PDF.

learn more

Design and Random Vibrational Analysis of Horizontal

2020年10月30日 Design and Random Vibrational Analysis of Horizontal Impact Hammer Crusher S. Naveen, P. Praveen Kumar Reddy, and S. L. N. Reddy Abstract During the crushing of a stone, sharpness of the blade decreases due to which deformations are observed on the blade, which reduce the efficiency of the

learn more

Crushing Plant Design and Layout Considerations - 911

2016年2月24日 • Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher’s discharge opening, as the production continues through an on-line coarse size analysis of the crushed product (digital image analyses). Dance, A. 2001) • More attention is being paid to the impact on crushing circuit design caused by variations

learn more

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

learn more

Design of impact stone crusher machine

2017年10月1日 Design of impact stone crusher machine. October 2017. Thesis for: Bachelor of Science. Advisor: Getaw Ayay. Authors: Tesfaye Olana Terefe. Indian Institute of Technology Delhi. To read the full ...

learn more

(PDF) Design and Construction of Rock Crushing

2018年8月7日 The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals ...

learn more

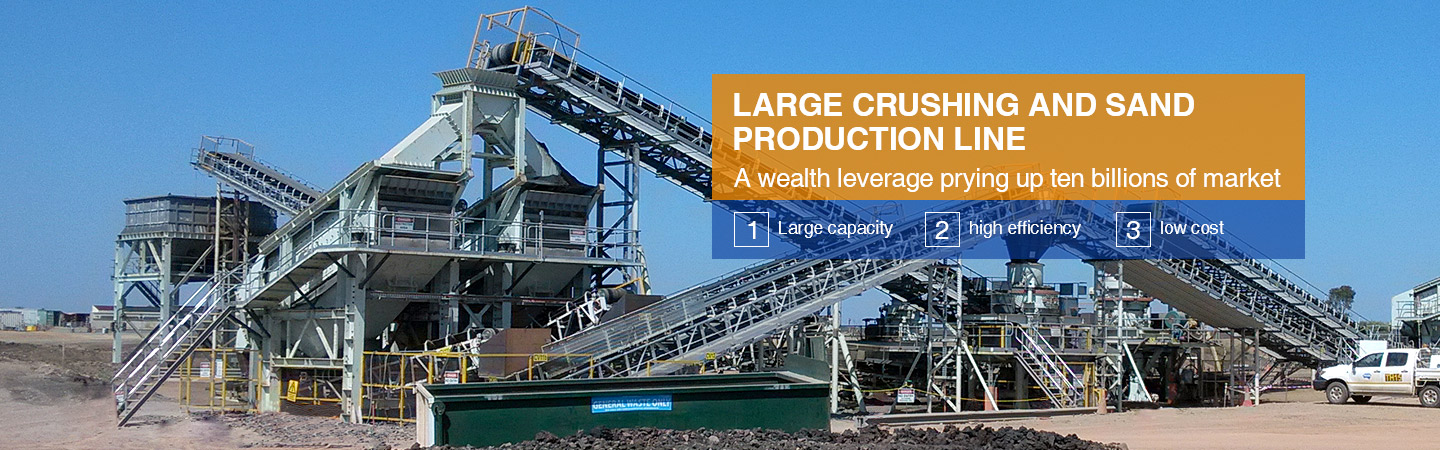

Crushing it: A Comprehensive Guide to Stone Crusher Plants

2023年2月28日 Introduction: A stone crusher plant is a machine designed to reduce the size of large rocks, eliminate gravel, or rock dust to smaller sizes for various applications. These plants find application in quarrying, mining, construction, and recycling operations. Stone crusher plants consist of several components, including a primary crusher,

learn more

« DESIGN OF A STONES CRUSHER MACHINE» - rufso

2022年4月11日 Therefore, the design of this machine is necessary. Fig. 1. A man crushing stone traditionally. Construction is clearly a critical enabling condition for improving living conditions in both rural and urban areas. This is achieved if and only if the stone crusher which will fill the demand of aggregates is designed.

learn more

Stone Crushers: A Technical Review on Significant Part of

2022年5月13日 Granite stone crusher Design + Analysis The design of stone crusher for crushing particle size between 25–135 mm to about 24–20.2 mm was done.ANSYS software is used to find out high region stress area as major factor for safe working of proposed equipment 2020 Tauyanashechikuku et al.[24] Zimbabwe 13 Secondary crusher

learn more

Engineering Design And Development Of A Small Capacity Stone Crusher ...

2013年2月6日 Presently for reducing sizes of stones from 4 X 4 to 1 X1 in. quarries is laborious job and is done manually. So development of smaller sized crusher is today’ s requirement. In this paper ...

learn more

(PDF) Design of a small-scale granite stone crusher

2020年1月1日 Tel.: +263713900710; fax: +263-242-303280. E-mail address: nyasharoy@gmail. various granite stones. A portable stone crushing machine was then designed which meets the minimum crushing force ...

learn more

Optimizing processing parameters of stone crushers through

2022年1月1日 B B V L Deepak [5] uses optimization in design and analysis of jaw plate of single toggle jaw crusher where the author analyzed the wear between jaw plate and material particle which is the main reason behind increase in the energy consumption. Kinematic analysis of commercially available swing jaw plate of 0.9 m wide with 304 mm

learn more

Rock Crushers, Stone Crushers, Screening and Crushing

200 kW. Capacity (by hour) 330 - 960 mtph (364 - 1,058 stph) Feed opening. 1,300 x 1,130 mm (51 x 45 in.) mm. Motor power. 160 kW (250 hp) Sandvik crushing and screening equipment. Unrivaled jaw crushers, cone crushers, gyratory crushers, impact crushers and more for mining and construction applications.

learn more