Rock Crushing 101: A Beginner's Guide Senya Crushers

2 天之前 Rock crushing is as straightforward as it sounds — using heavy machinery to break down larger rocks into smaller pieces. So many industries rely on crushed rock for

learn more

How it Works: Crushers, Grinding Mills and

2017年6月2日 Crushers. Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or

learn more

The Ultimate Guide to Rock Crushers Mellott

2024年5月30日 In this comprehensive guide, we delve into the world of rock crushers. We explore the different types, their uses, and the considerations when selecting the right

learn more

How does a Rock Crusher Work - Jaw Crusher - 911

2021年11月22日 Balanced flywheels offset reciprocating action smooth operation with minimum vibration. A JAW CRUSHER DESIGNED FOR OPERATORS. First—those who

learn more

Crusher - an overview ScienceDirect Topics

The primary gyratory crusher offers high capacity thanks to its generously dimensioned circular discharge opening (which provides a much larger area than that of the jaw

learn more

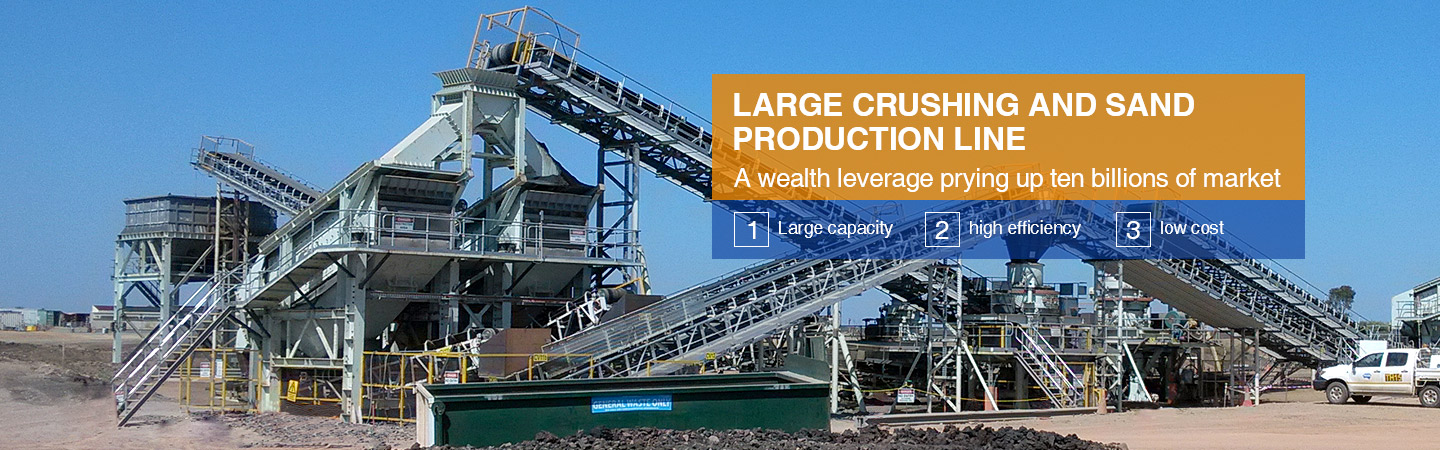

Crushing and Screening Handbook - AusIMM

2021年6月24日 quality rock materials for demanding construc-tion projects, such as bridges. Crusher automation – ensures consistent and effi cient operation. Improves

learn more

Mining - MineralProcessing - Rock Crusher - 4.2 Introduction

Rock crushers are used to process material within the mining process chain. Crushers are typically required ahead of conveyors, shafts or other transport or conveying devices.

learn more

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 Crushers are one of the essential quarrying machines used in foresaid industries which are generally used to reduce the size of large size rocks into small

learn more

Types Of Rock Crushers And When To Use Them

2023年1月16日 Rock crushers are necessary tools for most commercial and industrial projects involving the reduction of large rocks into smaller, more manageable pieces. Rock crushers come in many shapes and

learn more

How does an impact crusher work? RUBBLE

Impact crushers reduce mineral materials such as concrete, asphalt and natural rock in size to produce a valuable commodity product. A fast spinning rotor throws the material against a solid stationary impact wall.

learn more

Rock crusher production and operation cost analysis

2024年7月12日 A rock crusher production and operation cost is the sum total of direct and indirect costs incurred in producing a rock crusher. Direct costs include materials, labour, and overhead expenses while indirect costs include machine wear, depreciation, and transportation. Rock crushers are used to reduce rocks into smaller pieces.

learn more

Crusher - an overview ScienceDirect Topics

The type of jaw crusher depends on input feed and output product size, rock/ore strength, volume of operation, cost, and other related parameters. Heavy-duty primary jaw crushers are installed underground for uniform size reduction before transferring the ore to the main centralized hoisting system.

learn more

Rock Crushing 101: A Beginner's Guide Senya Crushers

2 天之前 Environmental regulations: Rock crushing operations must comply with local, state and federal regulations governing emissions, dust, noise and water use, among other things. High-efficiency equipment that minimizes resource usage and contains environmental controls is a must-have for streamlining compliance. ... An advanced rock

learn more

Rock Crusher Operator Safety Health Program Safety

2022年7月12日 Discuss the dangers from slips and falls when getting on or off of the crusher and maintain 3 points of contact when mounting or dismounting. Note: The wearing of a hard hat is mandatory, unless protected by a canopy. Provide an on site overview of the rock crushing process and how the employees should interact to provide for maximum

learn more

Cone Crushers (Parts of a Cone Crusher) Explained - saVRee

A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral(s) from the waste (gangue) material. Waste material can be discarded or recycled ...

learn more

Impact Crusher Working Principle - 911 Metallurgist

2015年6月23日 Impact Crusher Working Principle. Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what

learn more

Crushers - All crusher types for your reduction needs - Metso

In modern aggregates operations, the use of mobile primary crushers that can move alongside the rock face is, in many cases, the most economical solution. Primary crushing with jaw crushers In terms of the size of the feed opening, the client gets a better return on investment when the primary crusher is a jaw crusher.

learn more

Cone crusher basics in 4 minutes - rockprocessing.sandvik

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

learn more

How does a Rock Crusher Work - Jaw Crusher - 911

2021年11月22日 How does a Rock Crusher Work – Jaw Crusher. Jaw crushers include Superior, Type “B” Blake, Fine-Reduction, and Dodge — sizes, 4 by 6 to 84 by 66 inches. A reciprocating machine, the crushes material in a straight line between jaws — without grinding or rubbing surfaces. LOWER CRUSHING COSTS.

learn more

Rock Crusher - Eastman Rock Crusher

Mining operations use different kinds of crushers so selecting the appropriate crusher is important for every operation. Understanding the stages of crushing process and the types of crushers that best fit each

learn more

Types Of Rock Crushers And When To Use Them

2023年1月16日 Knowing what type of rock crusher to use for your project is essential in order to complete projects with maximum efficiency and minimal risk. Understanding the Different Stages of Rock Crushing. Rock

learn more

Optimization of Aggregate Production Circuit through

2022年1月9日 the power consumed during operation. This value was registered during the testing program and the unit energy consumption was ca lculated as a relationship of total power consumed to the throughput of the machine. Figure 2. Crushing device—impact crusher KU 65-120 during investigations (a); calibrating gap in the crusher (b).

learn more

The effect of rock crusher and rock type on the aggregate shape

2020年1月10日 It was reported by Hafeez et al. (2016) that rock aggregates produced through jaw and cone crushing circuits have a better cubical form when compared to those produced from the jaw crusher alone ...

learn more

Gyratory and Cone Crusher - ScienceDirect

2016年1月1日 Figure 5.1 is a typical sketch of a large gyratory crusher used as a primary crusher to reduce the size of large pieces of rocks produced during blasting in mines. Variations in the design of the breaking head and the mantle have been adopted by different manufacturers. Such variations are adopted from studies on stress distributions of

learn more

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

2017年6月30日 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

learn more

Types of Crushers: What You Need to Know - Machinery

Call us 24/7 or request a callback using the buttons below. Request a Callback. +1 800 329 3375. Supporting equipment all across the U.S. /. +1 800 329 3375. /. info@machinerypartner. Learn more about the different types of crushing and crushers used in the aggregates industry.

learn more

Minerals Free Full-Text Optimization of Aggregate

2021年11月6日 The paper concerns investigation of the effect of impact crusher operation on selected qualitative characteristics of mineral aggregate products. Qualitative characteristics of crushing products in terms of size reduction ratio and fine particles contents were analyzed from the point of view of operational parameters of the impact

learn more

HSE - Quarries - Safe operation and use of mobile jaw crushers

2024年6月13日 Being on the access platform during normal operation presents the following risks: Struck by objects ejected from the crusher, such as bits of stone or metal. The operation of the crusher catches being struck by any reinforcing bar as it. Being pulled into the crushing chamber when attempting to pull out contaminants (eg reinforcing bar).

learn more

SAFE WORK PROCEDURE FOR Crushing Operations

2021年7月28日 Crushing Operations Screener Operation ... Load the crusher with an excavator or loader, process it and screen the end product to be stockpiled. 2016-06-28 2:35 PM SP-12-02 Page 2 of 10 ... • Wrenches slipping • Injury • Amputations • Rock falling • Working in a danger zone PPE or Devices Required: • Eye Protection • Hard Hat ...

learn more